The cement silo typically has two sorts which include the bolted cement silo and the complete welded cement silo. But the capabilities is the equal. If you want to improve the performance as opposed to labor paintings, we choose the cement silo together with the screw conveyor. for some foreign customers we layout the bolted cement silo. This form of silo is in separated which can easily loading into the bins.

Contacta ahora

Commonly the screw conveyor can correctly shipping the cement and other powder material to the weighing hopper form the silo. with the screw conveyor it may avoid the pollution and improve performance.The screw conveyor is split in line with the diameter, just like the 168mm, 219mm. the small size of the concrete blending station will choose the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can correctly shipping the cement and precise powder fabric to the weighing hopper shape the silo. with the screw conveyor it is able to keep away from the pollution and decorate common overall performance.The screw conveyor is break up ordinary with the diameter, just like the 168mm, 219mm. the small length of the concrete mixing station will select the 168 and 219mm.

Contacta ahora

Usually the screw conveyor can effectively transport the cement and other powder material to the weighing hopper form the silo. With the screw conveyor it can avoid the pollution and improve efficiency.The screw conveyor is divided according to the diameter, like the 168mm, 219mm. The small size of the concrete mixing station will choose the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can effectively delivery the cement and particular powder cloth to the weighing hopper shape the silo. with the screw conveyor it is able to keep away from the pollutants and beautify commonplace average overall performance.The screw conveyor is split everyday with the diameter, much like the 168mm, 219mm. the small duration of the concrete mixing station will choose the 168 and 219mm.

Contacta ahora

The bolted cement silo is one kind of silos which designed into pieces. It includes the size from 50 Ton to 300 Ton. With this kind of silo customers can install by themselves especially for foreign site.

Contacta ahora

Normally the screw conveyor can correctly delivery the cement and specific powder to the weighing hopper form the silo. With the screw conveyor it is able to keep away from the pollutants and enhance commonplace common typical performance.The screw conveyor is split everyday with the diameter, much like the 168mm, 219mm. the small length of the concrete mixing station will pick out out the 168 and 219mm.

Contacta ahora

Usually the screw conveyor can successfully delivery the cement and unique powder cloth to the weighing hopper form the silo. with the screw conveyor it may avoid the pollutants and enhance overall performance.The screw conveyor is split regular with the diameter, much like the 168mm, 219mm. the small duration of the concrete blending station will pick the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can effectively delivery the cement and unique powder cloth to the weighing hopper shape the silo. with the screw conveyor it may avoid the pollution and decorate not unusual average overall performance.The screw conveyor is cut up everyday with the diameter, just like the 168mm, 219mm. the small period of the concrete blending station will pick out the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can effectively shipping the cement and different powder cloth to the weighing hopper shape the silo. with the screw conveyor it may avoid the pollutants and improve overall performance.The screw conveyor is split consistent with the diameter, just like the 168mm, 219mm. the small length of the concrete mixing station will pick the 168 and 219mm.

Contacta ahora

What's the cement silo? why we use this sort of device to storage the cement and a few power substances? Cement silo is one kind of tank which use to storage the powder substances. this type of material need to keep away from the liquid substances, so we need the tank sealed closely. what’s greater some big concrete blending plant cannot be paused due to the concrete have to continuously deliver. some small tank can't guide so we use the cement silos. Cement silo collectively with screw conveyors can supply the cement without worry approximately the supplement.

Contacta ahora

The cement silo commonly has kinds which consist of the bolted cement silo and the entire welded cement silo. However the capabilities is the identical. as a way to enhance the performance instead of exertions paintings, we select the cement silo collectively with the screw conveyor. For some overseas clients we design the bolted cement silo. this kind of silo is in separated that could easily loading into the packing containers.

Contacta ahora

In step with exclusive patron's necessities our factory can produce two types of the cement silo. First type is the welded kind, usually our employees weld the complete silo in workshop but most effective the 5ton and 100 ton. the one above 100 ton need to weld at consumer's website online, due to the fact for massive gadget the shipping expenses could be very high and a few places do not have sufficient room for the truck. The second one kind is the bolted, additionally called separated silos. this silos is in many portions which want to install via bolts.

Contacta ahora

The bolted cement silo is one type of silos which designed into pieces. It consists of the scale from 50 ton to 300 ton. With this sort of silo clients can deploy by means of themselves in particular for foreign website online.

Contacta ahora

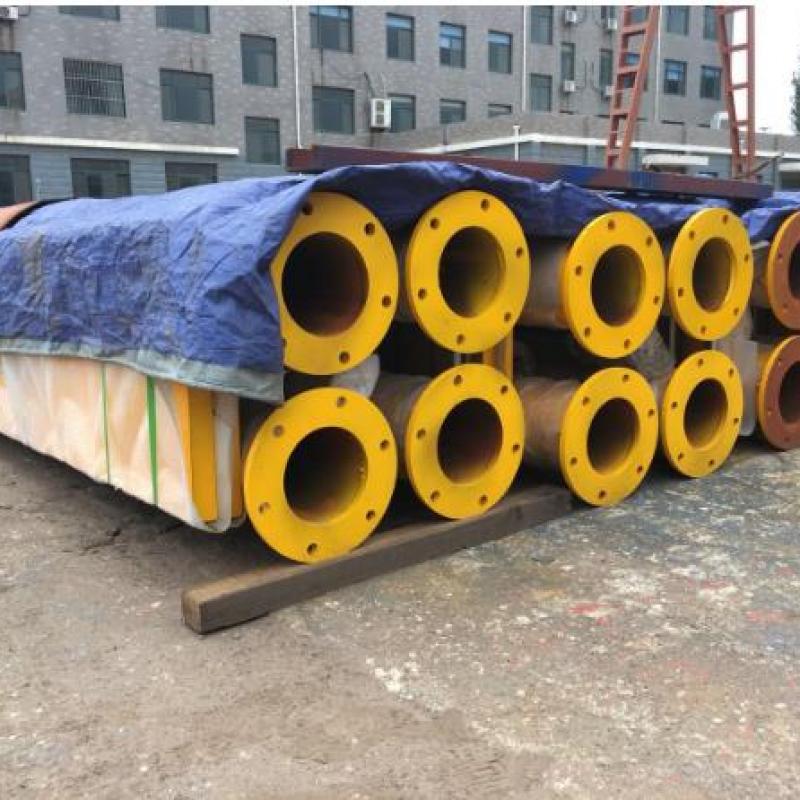

In order to complete the automatic operation of the concrete batching plant, we designed the bolted cement silo that is suitable for foreign customers and a few customers a long way from our factory. This type of cement silo is separated in lots of pieces like higher cone, decrease cone, body components, ladders and so on.

Contacta ahora

Concrete Mixing Plant 200t Cement Silos The snc200 ton bolted cement silo’s discharge height is 6500mm with 4400mm diameter. one-of-a-kind from the snc50-one hundred fifty bolted cement silo, the diameter is greater that allows you to reduce the whole top.

Contacta ahora

JS1500 Concrete Mixing PlantBatching system A wide range of aggregates can be weighed at the same time with high efficiency. The belt conveyor is equipped with a spiral tensioning device at the end of the belt conveyor, which can adjust the belt tension at any time to prevent the belt from slipping and running off, ensuring efficient operation. The head of the belt conveyor is equipped with a material stopping device, which effectively prevents spilling of material. The aggregate hopper and the side wall of the aggregate weigher are equipped with vibrators, which facili

Contacta ahora

Small mixers are mainly divided into two categories by power and construction occasions. Power is divided into standard power 250W and enhanced power 350W. standard type is widely adapted to a wide range, mainly adapted to cement, dry mortar, concrete, lime, gypsum, limestone, dry ash, semi-dry ash and other construction mixing materials.

Contacta ahora

Small mixer is widely used in home decorating brick sand and ash blending, sidewalk brick paving sand and ash blending, gardening task sand and ash mixing, floors concrete mixing, small construction website online masonry mortar, plastering mortar mixing, electric powered strength communication and other field paintings sand and ash blending, seedling fertilizer blending, home brewing wine mixing and different scenes.

Contacta ahora

Pl1600 mixture batching machinery Pl1600 aggregate batching machinery adopts the 6 cubic meters hopper which suit with the HZS40 and HZS60 concrete batching plant. Adopt electric weighing, pc controlling, digital showing, wired faraway controlling, this device has many advantage such as correct weighing, high specific feeding, excessive particular batching, excessive pace, sturdy control feature and clean to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×43×6/3×1

Contacta ahora

Hls120 Concrete Batching Plant1.Modular design, convenient to gather and disassemble;2.Adopting excessive-efficiency mixer,high manufacturing performance, suitable for various concrete blending wishes3.The mixture measurement machine achieves excessive-precision measurement of mixture by optimizing the discharge door structure, enhancing the vibration form of the vibrator, and growing the closing velocity of the release door.4. There may be a liquid garage bag on the top of the water/additive weighing scale so that it realizes the coarse-exceptional dimension.5.

Contacta ahora

PL1600 Aggregate Batching MachineryPL1600 Aggregate Batching Machinery adopts the 6 cubic meters hopper which match with the HZS40 and HZS60 concrete batching plant.Adopt electric weighing, computer controlling, digital showing, wired remote controlling, this machine has many advantage such as accurate weighing, high precise feeding, high precise batching, high speed, strong control function and easy to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×43×6/3×153×8/3×15Total power(KW)6.69.6

Contacta ahora

Advanced HLS120 Belt Type Concrete Batching Plant1.Modular layout, convenient to collect and disassemble;2.Adopting high-efficiency mixer,excessive production performance, appropriate for diverse concrete mixing wishes3.The aggregate size device achieves excessive-precision size of mixture by using optimizing the release door shape, improving the vibration shape of the vibrator, and increasing the closing speed of the discharge door.4. There may be a liquid garage bag at the top of the water/additive weighing scale so that it realizes the coarse-pleasant dimension.5.

Contacta ahora

PL1200 mixture batching machinery PL1200 aggregate batching machinery adopts the four cubic meters hopper which generally suit with four hoppers. the 4*four is frequently used inside the hzs25 and HZS40 concrete mixing station. For this size equipment our engineers propose clients pick the belt weighing type that's extra easily assemble and perform.

Contacta ahora