The cement silo typically has two sorts which include the bolted cement silo and the complete welded cement silo. But the capabilities is the equal. If you want to improve the performance as opposed to labor paintings, we choose the cement silo together with the screw conveyor. for some foreign customers we layout the bolted cement silo. This form of silo is in separated which can easily loading into the bins.

Contacta ahora

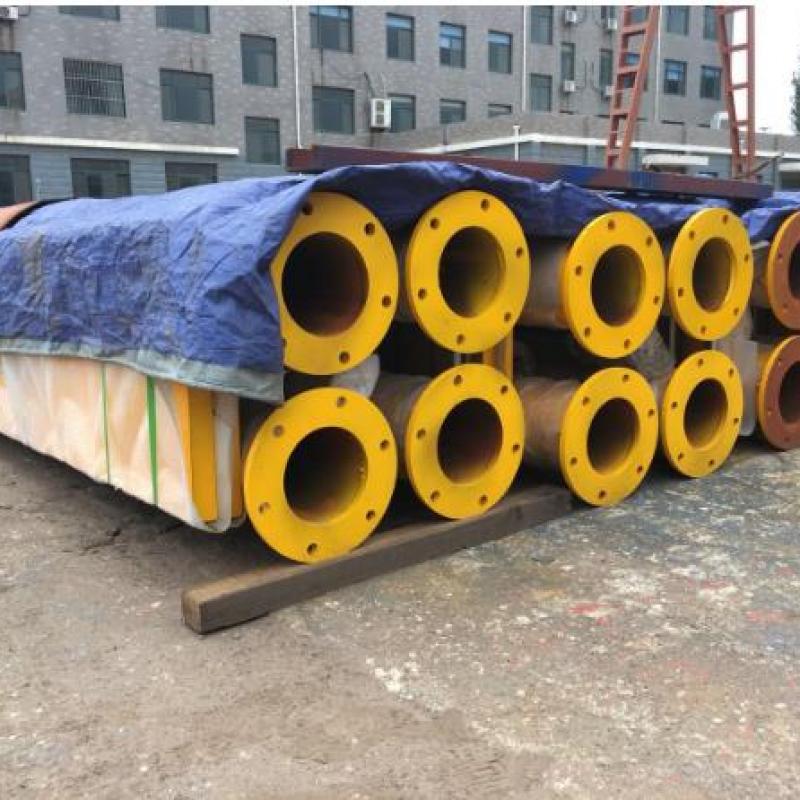

Usually the screw conveyor can effectively transport the cement and other powder material to the weighing hopper form the silo. With the screw conveyor it can avoid the pollution and improve efficiency.The screw conveyor is divided according to the diameter, like the 168mm, 219mm. The small size of the concrete mixing station will choose the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can effectively delivery the cement and particular powder cloth to the weighing hopper shape the silo. with the screw conveyor it is able to keep away from the pollutants and beautify commonplace average overall performance.The screw conveyor is split everyday with the diameter, much like the 168mm, 219mm. the small duration of the concrete mixing station will choose the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can correctly shipping the cement and other powder material to the weighing hopper form the silo. with the screw conveyor it may avoid the pollution and improve performance.The screw conveyor is split in line with the diameter, just like the 168mm, 219mm. the small size of the concrete blending station will choose the 168 and 219mm.

Contacta ahora

Usually the screw conveyor can successfully delivery the cement and unique powder cloth to the weighing hopper form the silo. with the screw conveyor it may avoid the pollutants and enhance overall performance.The screw conveyor is split regular with the diameter, much like the 168mm, 219mm. the small duration of the concrete blending station will pick the 168 and 219mm.

Contacta ahora

Normally the screw conveyor can correctly delivery the cement and specific powder to the weighing hopper form the silo. With the screw conveyor it is able to keep away from the pollutants and enhance commonplace common typical performance.The screw conveyor is split everyday with the diameter, much like the 168mm, 219mm. the small length of the concrete mixing station will pick out out the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can correctly shipping the cement and precise powder fabric to the weighing hopper shape the silo. with the screw conveyor it is able to keep away from the pollution and decorate common overall performance.The screw conveyor is break up ordinary with the diameter, just like the 168mm, 219mm. the small length of the concrete mixing station will select the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can effectively delivery the cement and unique powder cloth to the weighing hopper shape the silo. with the screw conveyor it may avoid the pollution and decorate not unusual average overall performance.The screw conveyor is cut up everyday with the diameter, just like the 168mm, 219mm. the small period of the concrete blending station will pick out the 168 and 219mm.

Contacta ahora

Commonly the screw conveyor can effectively shipping the cement and different powder cloth to the weighing hopper shape the silo. with the screw conveyor it may avoid the pollutants and improve overall performance.The screw conveyor is split consistent with the diameter, just like the 168mm, 219mm. the small length of the concrete mixing station will pick the 168 and 219mm.

Contacta ahora

The drive of the planetary mixer with vertical shaft is driven by a specially designed hardened gear reducer. A flexible coupling or a hydraulic coupling (optional) is installed between the motor and the reducer to ensure normal starting even at full load. The power generated by the reducer makes the stirring arm do both self rotation movement and rotation movement, and the scraper arm does the rotation movement.

Contacta ahora

The cement silo commonly has kinds which consist of the bolted cement silo and the entire welded cement silo. However the capabilities is the identical. as a way to enhance the performance instead of exertions paintings, we select the cement silo collectively with the screw conveyor. For some overseas clients we design the bolted cement silo. this kind of silo is in separated that could easily loading into the packing containers.

Contacta ahora

The drive of the planetary mixer with vertical shaft is driven by a specially designed hardened gear reducer. A flexible coupling or a hydraulic coupling (optional) is installed between the motor and the reducer to ensure normal starting even at full load. The power generated by the reducer makes the stirring arm do both self rotation movement and rotation movement, and the scraper arm does the rotation movement.

Contacta ahora

Hls180 concrete mixing plant is a huge-scale concrete blending plant evolved via our employer by using soaking up the blessings and superior technology of numerous models at home and overseas and combining our revel in of producing concrete mixing gadget for many years, which is composed of fabric conveying and garage machine, measuring machine, mixing machine, electric control machine, camera monitoring machine and metallic shape. It is suitable for large scale projects including roads, bridges, dams, airports, ports and other locations with high call for of commercial conc

Contacta ahora

What's the cement silo? why we use this sort of device to storage the cement and a few power substances? Cement silo is one kind of tank which use to storage the powder substances. this type of material need to keep away from the liquid substances, so we need the tank sealed closely. what’s greater some big concrete blending plant cannot be paused due to the concrete have to continuously deliver. some small tank can't guide so we use the cement silos. Cement silo collectively with screw conveyors can supply the cement without worry approximately the supplement.

Contacta ahora

The mainly superior gearbox can distribute the power stability to every mixing device successfully, which could ensure low noise transportation of blending faculties and universities even under harsh production situations.

Contacta ahora

PL2400 mixture batching equipmentThis length batching equipment normally matched for a few huge concrete blending station and sometimes we use the underground kind on the way to shop patron’s cost and can also achieve excessive efficiency.Normally the dimensions if 12 cubic meters and 15 cubic meters with belt weighing.

Contacta ahora

JS1500 Concrete Mixing PlantBatching system A wide range of aggregates can be weighed at the same time with high efficiency. The belt conveyor is equipped with a spiral tensioning device at the end of the belt conveyor, which can adjust the belt tension at any time to prevent the belt from slipping and running off, ensuring efficient operation. The head of the belt conveyor is equipped with a material stopping device, which effectively prevents spilling of material. The aggregate hopper and the side wall of the aggregate weigher are equipped with vibrators, which facili

Contacta ahora

Pl1200 aggregate batching equipmentPl1200 combination batching machinery adopts the 4 cubic meters hopper which generally healthy with four hoppers. the four*4 is regularly used in the hzs25 and hzs40 concrete blending station. For this size machinery our engineers recommend clients pick the belt weighing kind that's more effortlessly bring together and function.

Contacta ahora

Item500L750L1000L1250L1500L2000LFeeding Volume750L1125L1500L1875L2250L3000LFeeding Volume1200 kg1800 kg2400 kg3000 kg 3600 kg4800 kgOutput Volume500L750L1000L1250L1500L2000LMixing Power30/3737/4545/554555/7575/90Mixing star*Mixing Blade1*21*32*22*22*23*2Side Scraper/Discharge Scraper1/11/11/11/11/11/2Discharge power2.2kw2.2 kw2.2 kw2.2 kw2.2 kw3 kwWeight2500 kg3500 kg5500 kg6000 kg6500 kg8500kgHow to choose the mixer type? MPC vertical shaft planetary mixer and JS double horizontal shaft forced mixer have in common that they can be used as the main machine of concrete mixing plant.T

Contacta ahora

PL1600 Aggregate Batching MachineryPL1600 Aggregate Batching Machinery adopts the 6 cubic meters hopper which match with the HZS40 and HZS60 concrete batching plant.Adopt electric weighing, computer controlling, digital showing, wired remote controlling, this machine has many advantage such as accurate weighing, high precise feeding, high precise batching, high speed, strong control function and easy to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×43×6/3×153×8/3×15Total power(KW)6.69.6

Contacta ahora

Pl800 aggregate batching machinery Pl800 combination batching equipment adopts 2.five cubic meters hopper which can fit with to four hoppers. The measuring accuracy is about 2%, and we use weighing types encompass belt weighing and single hopper weighing. This kinds weighing kind each can provide accurate combination to the concrete mixer. And this form of batching equipment is popular in foreign market specially is africa marketplace. and we will use the impartial manage for the batching equipment and the concrete mixer that could store customers price.

Contacta ahora

Pl1200 mixture batching equipment PL1200 aggregate batching machinery adopts the 4 cubic meters hopper which commonly healthy with 4 hoppers. the 4*four is regularly used within the hzs25 and HZS40 concrete blending station. For this length equipment our engineers recommend customers pick the belt weighing type which is greater effortlessly gather and function.

Contacta ahora

Item500L750L1000L1250L1500L2000LFeeding Volume750L1125L1500L1875L2250L3000LFeeding Volume1200 kg1800 kg2400 kg3000 kg 3600 kg4800 kgOutput Volume500L750L1000L1250L1500L2000LMixing Power30/3737/4545/554555/7575/90Mixing star*Mixing Blade1*21*32*22*22*23*2Side Scraper/Discharge Scraper1/11/11/11/11/11/2Discharge power2.2kw2.2 kw2.2 kw2.2 kw2.2 kw3 kwWeight2500 kg3500 kg5500 kg6000 kg6500 kg8500kgHow to choose the mixer type? MPC vertical shaft planetary mixer and JS double horizontal shaft forced mixer have in common that they can be used as the main machine of concrete mixing plant.T

Contacta ahora

Pl1600 mixture batching machinery Pl1600 aggregate batching machinery adopts the 6 cubic meters hopper which suit with the HZS40 and HZS60 concrete batching plant. Adopt electric weighing, pc controlling, digital showing, wired faraway controlling, this device has many advantage such as correct weighing, high specific feeding, excessive particular batching, excessive pace, sturdy control feature and clean to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×43×6/3×1

Contacta ahora