Mobile Asphalt Mixing PlantMobility, efficiency, easily transportable mobile/portable batch asphalt mixing plantZAP-M models mobile/portable wheeled batch asphalt mixing plant are available from 80TPH to 160TPH• Easily transportable & assembling & disassembling. Saving time and cost of installation• Landing legs with support bases to ensure adequate stability• Low maintenance operation & energy consumption & emission• Multi-fuel burner• Fully automatic controlsCold Aggregate Feeding System- The belt feeder adopts frequency conversion speed regulation, wide speed

Contacta ahora

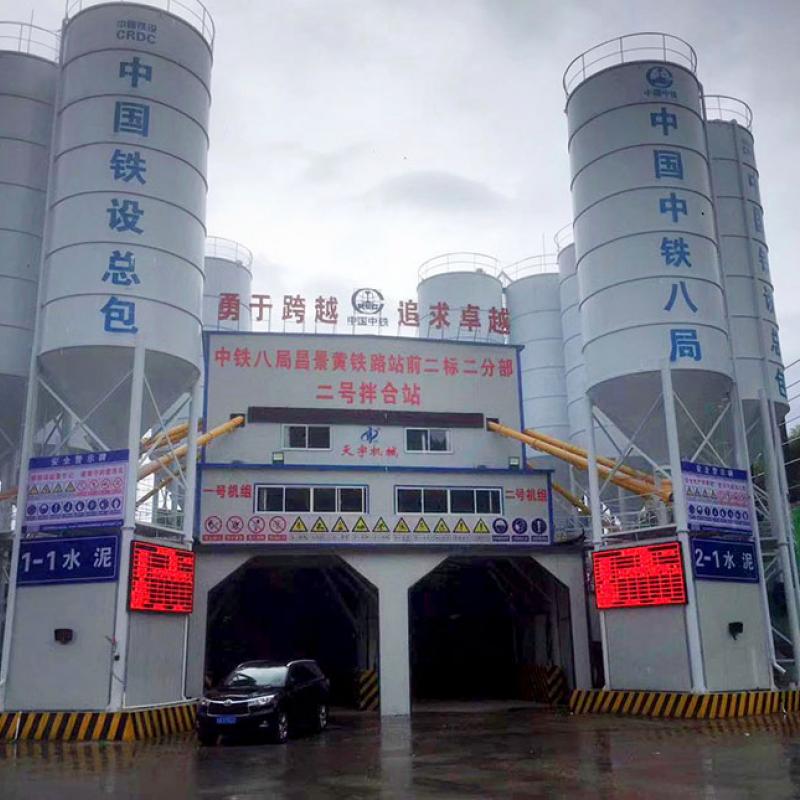

In order to complete the automatic operation of the concrete batching plant, we designed the bolted cement silo that is suitable for foreign customers and a few customers a long way from our factory. This type of cement silo is separated in lots of pieces like higher cone, decrease cone, body components, ladders and so on.

Contacta ahora

PL1600 Aggregate Batching MachineryPL1600 Aggregate Batching Machinery adopts the 6 cubic meters hopper which match with the HZS40 and HZS60 concrete batching plant.Adopt electric weighing, computer controlling, digital showing, wired remote controlling, this machine has many advantage such as accurate weighing, high precise feeding, high precise batching, high speed, strong control function and easy to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×43×6/3×153×8/3×15Total power(KW)6.69.6

Contacta ahora

PL2400 aggregate batching equipment This length batching equipment usually matched for some large concrete blending station and occasionally we use the underground type with the intention to keep consumer’s value and also can gain excessive efficiency. Usually the size if 12 cubic meters and 15 cubic meters with belt weighing.

Contacta ahora

PL800 aggregate batching equipment PL800 combination batching machinery adopts 2.5 cubic meters hopper which could suit with to 4 hoppers. the measuring accuracy is set 2%, and we use weighing sorts include belt weighing and unmarried hopper weighing. this two sorts weighing type both can provide accurate combination to the concrete mixer. And this kind of batching machinery is famous in foreign market especially is africa marketplace. and we are able to use the unbiased control for the batching machinery and the concrete mixer which could shop customers cost.

Contacta ahora

Pl1600 combination batching equipment Pl1600 combination batching machinery adopts the 6 cubic meters hopper which in shape with the HZS40 and HZS60 concrete batching plant. Undertake electric weighing, computer controlling, digital displaying, wired faraway controlling, this system has many advantage such as correct weighing, excessive particular feeding, high precise batching, excessive speed, sturdy manage feature and easy to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×

Contacta ahora

Pl1600 mixture batching machinery Pl1600 aggregate batching machinery adopts the 6 cubic meters hopper which suit with the HZS40 and HZS60 concrete batching plant. Adopt electric weighing, pc controlling, digital showing, wired faraway controlling, this device has many advantage such as correct weighing, high specific feeding, excessive particular batching, excessive pace, sturdy control feature and clean to operate.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×43×6/3×1

Contacta ahora

The concrete blending plant is specifically divided into four components: gravel feeding, powder feeding, water and admixture feeding, transfer mixing and storage. the complete frame of the plant is product of steel shape, and the remarkable h-fashioned metal now not best has a lovely appearance, however also strengthens the general structural strength of the concrete mixing plant, which is simple to install and may be applied to diverse complex terrain systems.The concrete blending plant has desirable blending overall performance.

Contacta ahora

The concrete mixing plant is mainly divided into four parts: gravel feeding, powder feeding, water and admixture feeding, transfer mixing and storage. The whole body of the plant is made of steel structure, and the high-quality H-shaped steel not only has a beautiful appearance, but also strengthens the overall structural strength of the concrete mixing plant, which is easy to install and can be applied to various complex terrain structures.The concrete mixing plant has good mixing performance.

Contacta ahora

The concrete blending plant is in particular divided into four additives: gravel feeding, powder feeding, water and admixture feeding, transfer blending and storage. the entire frame of the plant is made from metal shape, and the amazing h-long-established metal not satisfactory has a cute look, however also strengthens the overall structural power of the concrete mixing plant, which is simple to put in and may be implemented to diverse complicated terrain systems. The concrete mixing plant has ideal mixing usual overall performance.

Contacta ahora

The concrete blending plant is particularly divided into four elements: gravel feeding, powder feeding, water and admixture feeding, transfer mixing and garage. the complete frame of the plant is made from metallic shape, and the first-rate h-fashioned metallic no longer simplest has a beautiful appearance, however also strengthens the overall structural strength of the concrete blending plant, which is straightforward to put in and may be applied to various complex terrain systems.The concrete blending plant has precise mixing overall performance.

Contacta ahora

Hls120 Concrete Batching Plant1.Modular design, convenient to gather and disassemble;2.Adopting excessive-efficiency mixer,high manufacturing performance, suitable for various concrete blending wishes3.The mixture measurement machine achieves excessive-precision measurement of mixture by optimizing the discharge door structure, enhancing the vibration form of the vibrator, and growing the closing velocity of the release door.4. There may be a liquid garage bag on the top of the water/additive weighing scale so that it realizes the coarse-exceptional dimension.5.

Contacta ahora

HLS180 concrete mixing plant is a large-scale concrete mixing plant developed by our company by absorbing the advantages and advanced technologies of various models at home and abroad and combining our experience of producing concrete mixing equipment for many years, which is composed of material conveying and storage system, measuring system, mixing system, electrical control system, camera monitoring system and steel structure. It is suitable for large scale projects such as roads, bridges, dams, airports, ports and other places with high demand of commercial concrete in c

Contacta ahora

1. Modular design, clean to disassemble hzs25 concrete mixing plant adopts combined structure and modular unit, which may be very handy to put in and relocate.2. Excessive mixing first-rate the primary device of hzs25 concrete mixing plant adopts js500 double horizontal shaft forced concrete mixer, which has right mixing excellent and excessive efficiency.3. Specific size the aggregate batching adopts pld800 concrete batching system, which has accurate dimension and high production performance.

Contacta ahora

Bucket Concrete Batch Plant HZS120 Concrete Mixing Station is composed of aggregate batching system, electrical control system, weighing system, mixing system, , pneumatic control system and etc. With JS2000 concrete mixer and the 4*15 cubic meters batching machinery. The rated productivity is 120 cubic meters concrete per hour.

Contacta ahora

Pl800 mixture batching equipmentPl800 mixture batching machinery adopts two of five cubic meters hopper that can suit with to four hoppers. the measuring accuracy is ready 2%, and we use two weighing kinds encompass belt weighing and unmarried hopper weighing. this sorts weighing type both can provide accurate aggregate to the concrete mixer.And this type of batching equipment is famous in overseas marketplace specifically is africa market. and we can use the unbiased control for the batching machinery and the concrete mixer which could save customers value.

Contacta ahora

Planetary mixer has a completely unique and novel shape of blending, the kettle has or 3 multi-layer slurry blade stirrer and 1 to two automatic scrapers, the stirrer within the axis of the kettle body whilst rotating round its personal axis at exceptional speeds, excessive-pace rotation, in order that the material within the kettle body for complex motion, problem to strong shear and rub collectively its performance is typically several times the everyday mixer. Planetary mixer features: the host adopts planetary equipment reducer layout, low noise, high mechanical efficien

Contacta ahora

Advanced HLS120 Belt Type Concrete Batching Plant1.Modular layout, convenient to collect and disassemble;2.Adopting high-efficiency mixer,excessive production performance, appropriate for diverse concrete mixing wishes3.The aggregate size device achieves excessive-precision size of mixture by using optimizing the release door shape, improving the vibration shape of the vibrator, and increasing the closing speed of the discharge door.4. There may be a liquid garage bag at the top of the water/additive weighing scale so that it realizes the coarse-pleasant dimension.5.

Contacta ahora

PL800 Aggregate Batching MachineryPL800 Aggregate Batching Machinery adopts 2.5 cubic meters hopper which can match with two to four hoppers. The measuring accuracy is about 2%, and we use two weighing types include belt weighing and single hopper weighing. This two kinds weighing type both can provide accurate aggregate to the concrete mixer.And this kind of batching machinery is popular in foreign market especially is Africa market. And we can use the independent control for the batching machinery and the concrete mixer which can save customers cost.

Contacta ahora

1. The primary blending device adopts js2000 double horizontal shaft forced concrete mixer, which has excellent mixing quality and excessive productiveness, and may entire exact blending of dry difficult, semi-dry hard, plastic and diverse ratios of concrete in ideal time;2. The general shape of hzs120 concrete mixing plant is atmospheric, which can be disassembled and assembled speedy and transported readily;3. A diffusion of different arrangements may be selected to match the neighborhood conditions and adapt to the web page requirements;4.

Contacta ahora

Advantage1.Concrete mixing plant adopts combined shape and modular unit, which could be very convenient to put in and relocate.2. High blending best the primary gadget of hzs25 concrete mixing plant adopts js500 double horizontal shaft compelled concrete mixer, which has good mixing quality and excessive performance.3. Specific measurement the aggregate batching adopts pld800 concrete batching device, which has accurate dimension and high production efficiency.

Contacta ahora

Pl1200 mixture batching equipment PL1200 aggregate batching machinery adopts the 4 cubic meters hopper which commonly healthy with 4 hoppers. the 4*four is regularly used within the hzs25 and HZS40 concrete blending station. For this length equipment our engineers recommend customers pick the belt weighing type which is greater effortlessly gather and function.

Contacta ahora

PL1600 mixture batching equipment Pl1600 mixture batching machinery adopts the 6 cubic meters hopper which fit with the hzs40 and hzs60 concrete batching plant. Adopt electric weighing, pc controlling, virtual displaying, stressed far off controlling, this gadget has many benefit along with correct weighing, excessive precise feeding, excessive precise batching, high pace, robust control characteristic and clean to function.ModelPL800A/BPL800C/DPL800EPL800F/UPL1200GPL1600PL2400Scale hopper capacity (L)800800800800120016002400Storage bincapacity (m3)2×2.53×2.54×2.53×43×

Contacta ahora

PL1200 mixture batching machinery PL1200 aggregate batching machinery adopts the four cubic meters hopper which generally suit with four hoppers. the 4*four is frequently used inside the hzs25 and HZS40 concrete mixing station. For this size equipment our engineers propose clients pick the belt weighing type that's extra easily assemble and perform.

Contacta ahora